| WP No | WP Title | Lead Participant Short Name |

| 1, 2, 3 | Consortium management activities RP1, RP2, RP3 To efficiently manage the X-SeeO2 consortium, ensuring smooth project progress through continuous oversight and timely updates of all required documentation and actions. | UMA |

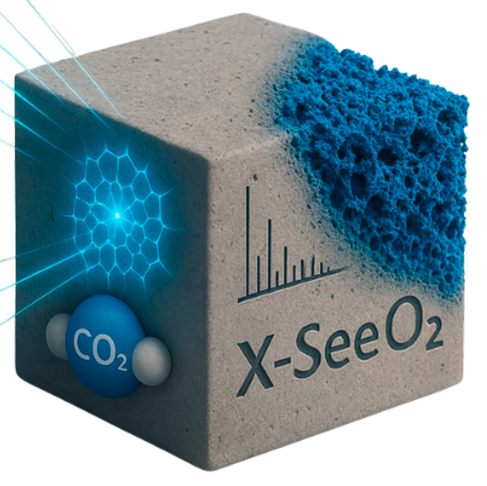

| 4 | Synchrotron facility technical developments To tailor the existing capillary cell at ESRF for in-situ powder diffraction analyses of CO2 mineralisation of cementitious materials. To develop a cell for in-situ X-ray imaging of CO2 mineralisation of cementitious materials. To collect synchrotron data in a robust and tailored way to produce relevant scientific information. | ESRF |

| 5 | Data acquisition RP1-2 To facilitate the ex-situ and in-situ synchrotron data acquisitions for the consortium and the portfolio. To facilitate laboratory micro computed tomography data acquisitions for the consortium and the portfolio. | UMA |

| 6 | Data acquisition RP3 To facilitate the ex-situ and in-situ synchrotron data acquisitions for the consortium and the portfolio | UMA |

| 7 | Robust X-ray powder diffraction analyses To agree, within the portfolio, sample preparation protocols for analysing representative samples with the lowest possible degree of alteration/bias. To elaborate a workflow for the powder diffraction analyses to be followed by all partners of X-SeeO2. To coordinate and contribute to the SXRPD data analyses for the experiments selected by the BSP. | UMA |

| 8 | Robust X-ray imaging analyses with focus on CO2 uptake To elaborate a workflow for a robust X-ray imaging data analysis to be followed by all members of X-SeeO2. To coordinate and contribute to the (S,L)XRmCT data analyses for the experiments selected by the BSP. | UoM |

| 9 | CS1: Novel SCMs produced via mechanochemical activation under CO2 Defining the links between MCA processing parameters and the nature of the precursor used, with the microstructure alterations of treated materials. Optimisation of in-situ/ex-situ CO2 mineralisation of mechano-chemically activated cement replacements to produce carbon neutral SCMs. Determining the effectiveness of MCA treated materials to produce blended PC cements | UoB |

| 10 | CS2: High-throughput determination of CO2 uptake kinetics in PCs and blends To determine the kinetics of the CO2 mineralisation processes as a function of the type of starting cementitious materials and pre-curing (H2O) and curing (CO2) experimental conditions. To characterise the microstructure and performances of selected cementitious materials under the optimised (water) pre-curing and (CO2) curing conditions. | UMA |

| 11 | Portfolio activities Explore synergies and collaborations among the projects of the portfolio, to maximize the achievement of the scientific results, the exploitation potentials, the outreach opportunities with key stakeholders, the identification and overcoming of major barriers to introduce the innovation to the market | UMA |

| 12 | Dissemination, communication and exploitation activities To coordinate and develop the communication, dissemination and exploitation (CDE) activities | UMA |