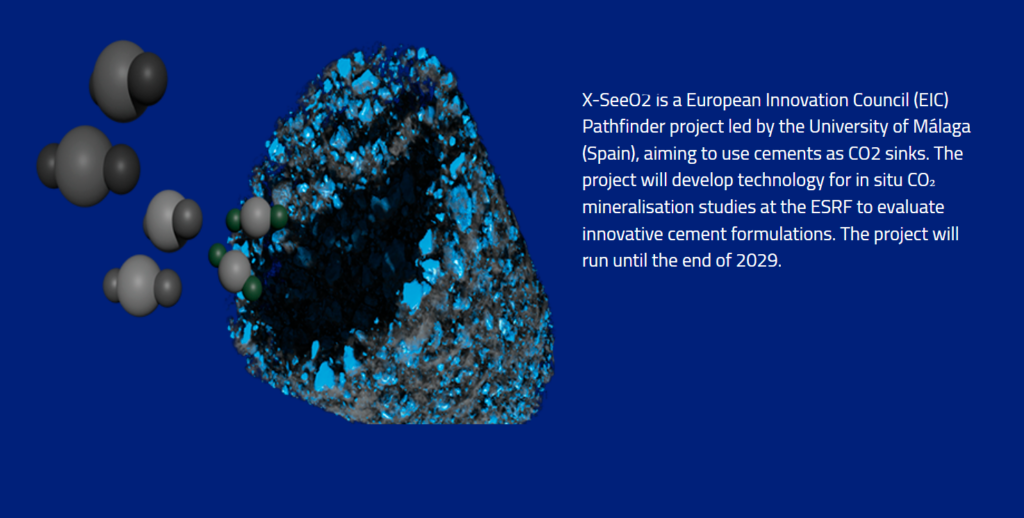

X-SeeO2 is a European Innovation Council (EIC) Pathfinder project led by the University of Málaga (Spain), aiming to use cements as CO2 sinks.

The project will develop technology for in situ CO₂ mineralisation studies at the ESRF to evaluate innovative cement formulations. The project will run until the end of 2029.

Cement is the largest manufactured product in the world by mass. Current cement technologies emit 8% of our CO2 emissions (about 600 kg per capita), which are ‘embodied’ in buildings and infrastructures. Roughly 60% of these emissions are ‘chemical’ released by converting limestone into clinker, and 40% of doing so at very high temperatures by burning fossil fuels.

With the aim of reducing radically CO2 emissions from cement, one obvious pathway would be to capture and store CO2 of current production processes. However, innovative and realistic solutions are not yet a reality.

Through its Pathfinder Challenge, the European Innovation Council has granted close to 24 millions to six projects, by academics and industries, that present new strategies to accelerate the use of cements as carbon dioxide ‘sinks’, to reduce emissions. One of these projects, X-SeeO2, led by the University of Málaga’s professor Miguel Ángel Aranda, intends to develop innovative technologies to support sustainable cement production by capturing and using CO₂ emissions. To achieve this, Aranda has joined forces with the ESRF, the University of Manchester and the University of Bath.

Diffraction and imaging on CO2 curing of cements

At the ESRF, scientists will develop the technology for in situ CO2 studies in powder diffraction and imaging on beamlines ID22 and ID19, respectively. “We chose the ESRF as our partner because of the great efficiency achieved with the upgrade: very fast measurements and a very reliable machine”, says Aranda. “Also, at the ESRF we have experts that can help us design and implement all the needed technology for the studies of CO2 mineralisation”, he adds.

On ID19, researchers from the ESRF, together with a post-doctoral researcher funded by X-SeeO2, will develop a new cell to study Portland cement with CO2 curing in real-life pressure ranges (1-4 bar) and with temperature control. On ID22, they will tailor the existing cell used to study CO2-uptake by MOFs for the analysis of CO2 mineralisation within cementitious materials. Michael Krisch, director of research at the ESRF, explains the significance of this project: “Our involvement in the EIC Pathfinder X-SeeO₂ project highlights the importance of the ESRF’s advanced diffraction and imaging capabilities in enabling breakthrough research on low-carbon cements.”

Another aim of this project is to create a unified data analysis workflow. “The bottleneck in experiments is not the experiments themselves, but the data analysis. We want to create a pipeline where scientific results, one level above processed data, can be easily exported to interested parties”, explains Aranda. In this respect, Aranda envisages the creation of a so-called Atlas for building materials, where experts could access data information in a centralised system. Moreover, to this end, each of the X-SeeO2 partners has secured funding for a Postdoctoral researcher that will analyse data for the consortium and chiefly, for the EIC-portfolio of five additional projects. X-SeeO2 has been selected as the ‘Enabling Technology’ provider (i.e. diffraction and tomography) for the portfolio of projects.

This project has received funding from the European Union’s Horizon Europe research and innovation programme [EIC-Pathfinder Challenges] under grant agreement No 101220926, project acronym ‘X-SeeO₂’.

Text by Montserrat Capellas Espuny